|

|

|

Terminal

Crimp Process Verification Report |

|

|

|

|

|

|

Report No.: |

|

|

|

Project Name: |

|

Manufacturer: |

|

|

|

Project Type: |

|

Preparing Location: |

|

|

|

Requested By: |

|

Request Date: |

|

|

|

|

|

|

Prepared By: |

|

Completion Date: |

|

|

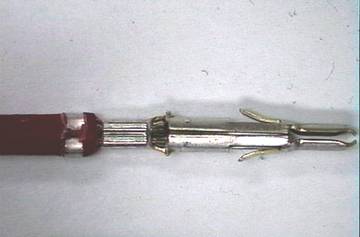

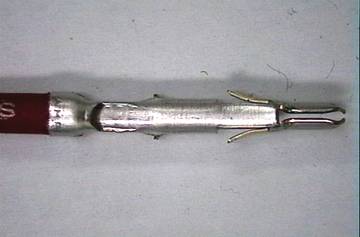

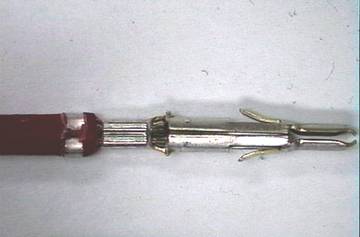

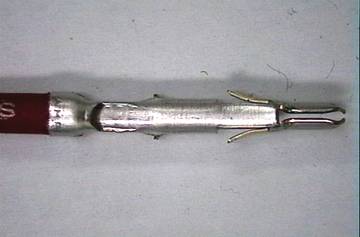

| Configuration &

Visual Inspection Photo |

|

|

Observations: |

|

|

|

|

|

| The overall crimp and terminal visual

inspection: |

|

| Based on visual inspection,

classify this crimp as acceptable, process issue, or design issue. |

|

|

| |

|

|

|

| Check

Points: |

Classification |

|

| Terminal mating area is not damaged by the crimping process. |

Acceptable |

|

|

| Deformation of the terminal from the crimping process is within

supplier's specification. |

Acceptable |

|

|

|

| Both the Insulation and Conductor are visible in the terminal

inspection window. |

Acceptable |

|

|

| There

are no wire strand nicks. |

Acceptable |

|

|

The

insulation has an even cut with no tearing (jagged edges). |

Acceptable |

|

|

| Insulation

does not extend into the conductor crimp. |

Acceptable |

|

|

| Bell

mouth(s) on conductor crimp meet supplier's specification. |

Acceptable |

|

|

| Wire

brush is visible, uniform, and evenly distributed. |

Acceptable |

|

|

| Wire brush does not interfere with the terminal's mating

section. Wire brush meets supplier's

specification. |

Acceptable |

|

|

|

| Visual inspection of terminal shows no signs of material

cracking as a result of the crimping process. |

Acceptable |

|

|

|

|

Additional Comments: |

|

|

|

|

| |

|

|

|

|

|

|

|

|

| Measurement

Criteria |

|

|

|

1. Visual Acceptance Criteria for Crimped

Terminals |

|

|

|

|

2. IPC-A-620 |

|

|

3. SAE/USCAR-21 |

|

|

4. OEM Application/ Material Specifications

and Crimping Guides |

|

| |

|

|

|

|

|

|

|

| |

|

|

|

|

|

|

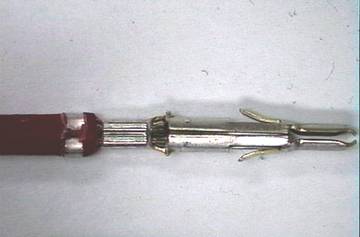

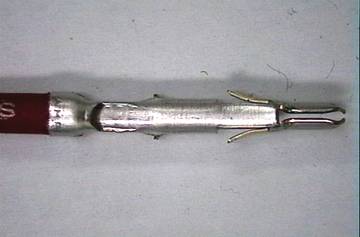

| Category |

Measurement |

Specification |

Meets Criteria? |

|

| Bellmouth Brush

End |

.029 mm |

0.25+0.00/-0.25 |

Yes |

|

| Bellmouth Entry

End |

0.17 mm |

0.13 mm to 0.76 mm |

Yes |

|

| Cut off Tab #1

(front) |

.086 mm |

0.13 mm to 0.76 mm |

No |

|

| Cut off Tab #2

(wire end) |

N/A |

N/A |

Yes |

|

| Brush Length |

0.87 mm |

1.02 mm / max |

Yes |

|

| Insulation

Inspection Window - comments |

Visible and acceptable |

|

|

|

| Conductor

Crimp Seam - comments |

Closed enough, no visible strands

through it |

|

|

| Twist

& Roll - comments |

Straigth application |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|