|

|

|

Terminal

Crimp Process Verification Report |

|

|

|

|

|

|

Report No.: |

|

|

|

Project Name: |

|

Manufacturer: |

|

|

|

Project Type: |

|

Preparing Location: |

|

|

|

Requested By: |

|

Request Date: |

|

|

|

|

|

|

Prepared By: |

|

Completion Date: |

|

|

|

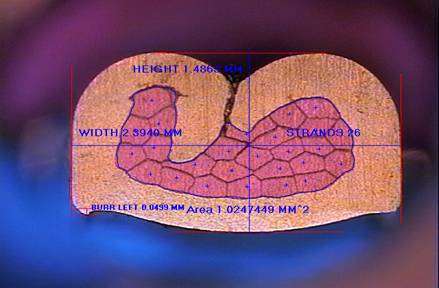

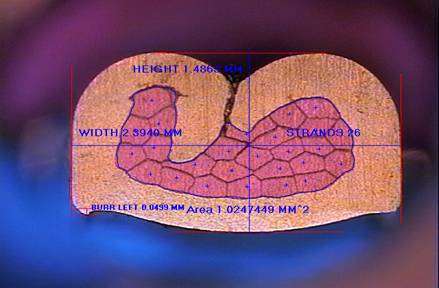

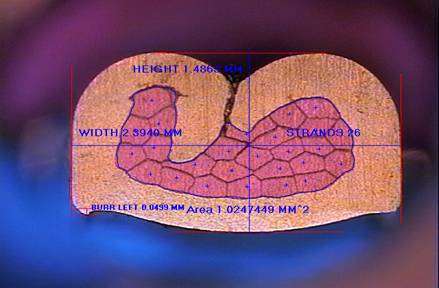

| Conductor Crimp

Cross Section |

|

| Cross Section Close to Conductor Crimp Center |

Observations |

|

|

Evaluation based on IPC A-620 sec. 5.1.1 |

|

|

|

| Based on observations, classify

this insulation crimp cross section as acceptable, process issue, or design

issue. |

|

|

| Check

Points: |

Classification |

|

| Compression: No round strands.

All strands are deformed. |

Acceptable |

|

|

| The crimp is symmetrical.

The distance between wing tips is not greater than the material

thickness of the terminal. Strands are

evenly distributed. |

Process Issue |

|

|

|

|

| No air gaps in the conductor crimp. |

Acceptable |

|

| No cracks or breaks in the terminal material (normally linked to

excessive extrusion.) |

Acceptable |

|

|

|

| Wings Locked. No gaps between wings. |

Acceptable |

|

| Wing tips do not contact bottom or side of terminal. |

Acceptable |

|

|

| Additional

Comments: |

|

| |

|

|

|

|

|

|

| Center Wire Crimp

Analysis |

|

| Category |

Measurement |

Specification |

Meets Criteria? |

|

| Height** |

1.505 |

1.49 +/- 0.05 |

Yes |

|

| Width* |

2.30 mm |

2.29 mm |

Yes |

|

| Pull Test** |

62.1 |

40 lbs. |

Yes |

|

| Wire Barrel Flash

/ Extrusion |

0.0499 mm |

0.0 mm |

0.25 mm |

Yes |

|

| Wire CMA |

2600 |

2600 |

Yes |

|

| Strand Count |

0 |

26 |

Yes |

|

| Strand Diameter |

0.254 mm |

0.254 |

Yes |

|

| Crimp Compression* |

22.22% |

10% <= 30%*** |

Yes |

|

| *Measurements

are from a 1 piece sample set |

|

| **Measurements

are the mean of a 30 piece sample set. |

|

| ***For

copper wire material only |

|

|

| Measurement

Criteria |

|

|

1. IPC-A-620 |

|

|

2. SAE/USCAR-21 |

|

|

3. OEM Application / Specifications, UL 758

and Good Crimping Guides |

|

|

4. C-4 - 7.3.4 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|