| |

| |

| |

| |

|

| |

| |

|

MPN Brochure

|

| |

|

Pull Tester Station PDF

|

| |

| |

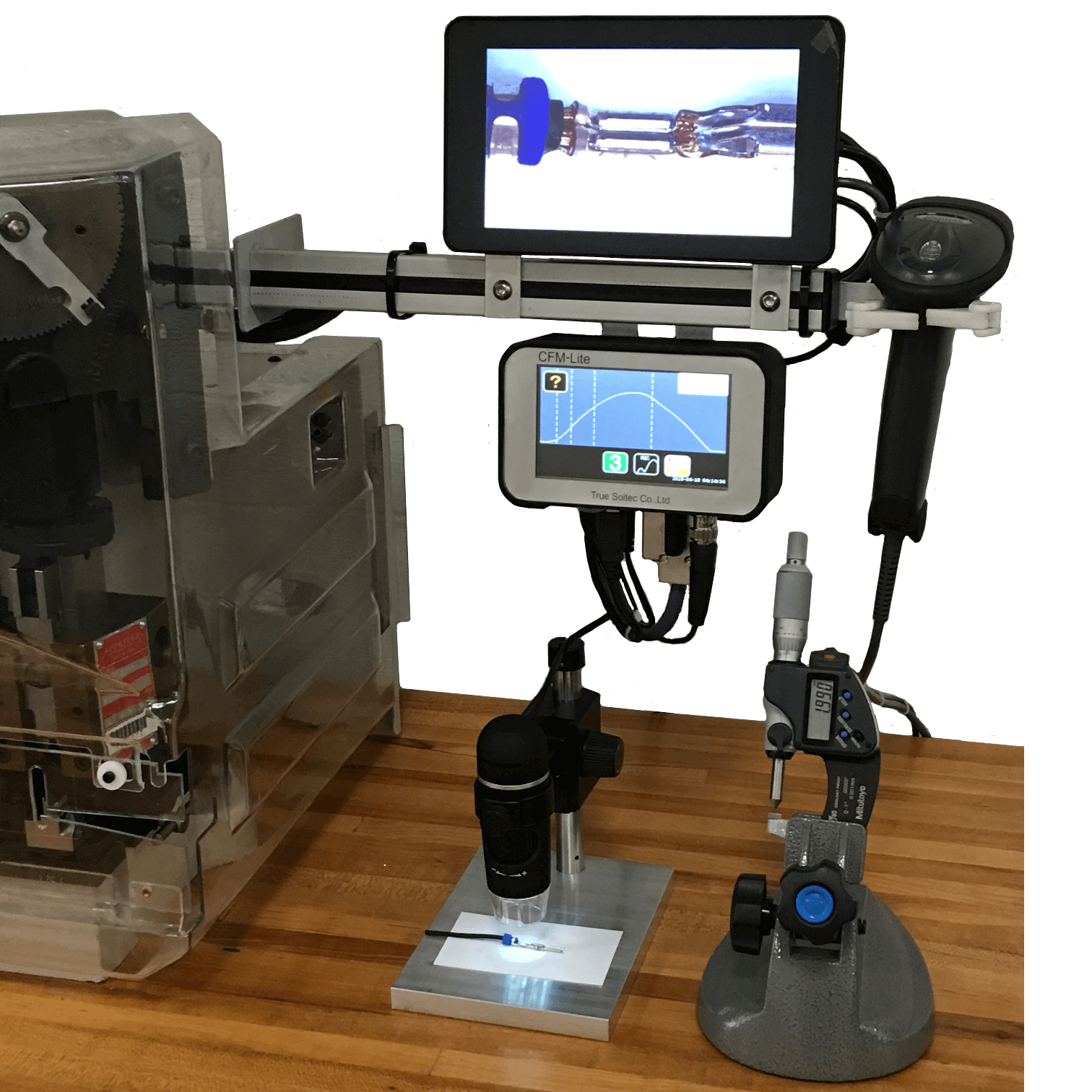

| Features: |

- Seven inch color touch screen user interface

- Control cabinet provides for 20 inputs and 20 outputs for connection to various sensors and switches on the crimp press.

- An aluminum reel clamp with integrated micro switch provides a signal every time the terminal reel is changed. The operator is required to scan the terminal part number and measure the crimp height.

- A sensor is installed in the base plate under the applicator. Every time the applicator is removed the operator is required to measure the crimp height.

- A Crimp Height Micrometer is set at each crimp press and must be used at setup time, at every reel change and whenever the applicator is removed.

- Groups of crimp presses can share one pull tester, cross section station, bend angle station.

- "Smart" choppers can be installed at each press to assure accountability of all crimp defects.

- Inexpensive, compact USB microscopes can be installed at each crimp press for visual inspection and saving of pictures for traceability.

|

| |

| MPN 100 is a comprehensive network system designed for manual crimp presses. All your manual presses are connected wirelessly to a server PC. The server PC has a database with all the relevant data for each circuit like terminal part numbers, crimp heights, pull test values, wire part number, applicator ID, seal part number, etc.

|

| |

| At setup time a barcode scanner is used to scan worker ID, wire part number, terminal part number, applicator ID. A complete setup validation is required including visual parameters, crimp height measurements and pull test. Any and all data related to the daily production is captured and stored. |

| |

| MPN 100 can also interface with Crimp Force Monitor, "Smart" chopper, Cross section station, Bend angle station, USB microscope. |

| |

| |

|

| |

| |

|

| |

|

| |

|

| |

| |

|